Understanding the Significance of Automatic Packaging Machines in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the significance of an automatic packaging machine cannot be overstated. As industries strive for greater efficiency and consistency, these advanced machines are revolutionizing the way products are packaged and presented to consumers. By integrating cutting-edge technology and automation, businesses can not only streamline their production processes but also enhance the overall quality of their output. Automatic packaging machines are designed to handle a variety of tasks—from sealing and labeling to collating and wrapping—while minimizing human error and maximizing speed. In this blog, we will explore the diverse applications and benefits of these machines, highlighting why they have become an indispensable component in the manufacturing arena. Emphasizing both operational effectiveness and cost savings, we will uncover how embracing automation in packaging can propel manufacturers into a new era of productivity and competitiveness.

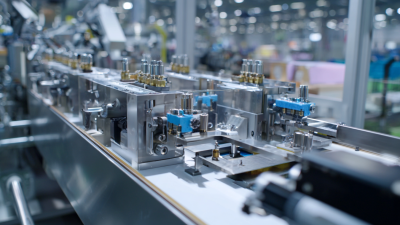

The Evolution of Automatic Packaging Machines in Manufacturing

The evolution of automatic packaging machines has dramatically transformed the landscape of modern manufacturing. From their humble beginnings in the early 20th century, these machines have undergone significant advancements in technology and efficiency. According to a report by Grand View Research, the global packaging machinery market size was valued at approximately $43.4 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 5.7% from 2021 to 2028. This growth is a testament to the increasing demand for faster and more efficient packaging solutions across various industries, including food and beverage, pharmaceuticals, and consumer goods.

Improvements in automation and robotics have played a crucial role in this evolution. Modern automatic packaging machines are equipped with advanced features such as machine learning algorithms and predictive maintenance capabilities, which enhance operational efficiency and reduce downtime. A study by Allied Market Research predicts that the integration of robotics in packaging machinery could lead to a productivity increase of up to 30% by 2025. This shift not only streamlines production processes but also allows manufacturers to respond swiftly to market demands while maintaining high quality and reducing labor costs. The ongoing advancements in packaging technologies continue to shape the future of manufacturing, paving the way for smarter and more sustainable practices.

Key Benefits of Implementing Automatic Packaging Solutions

Automatic packaging machines have become an essential element in modern manufacturing, offering a multitude of benefits that enhance operational efficiency. According to a report by Smithers Pira, the global market for automatic packaging machinery is projected to reach $60 billion by 2024, reflecting the growing demand for speed and consistency in the production line. These machines not only streamline the packaging process but also significantly reduce labor costs, as manufacturers can operate with fewer personnel while increasing output rates. In fact, implementing automatic packaging can boost production speed by as much as 50%, leading to faster turnaround times and improved supply chain reliability.

In addition to speed and cost savings, automatic packaging solutions also improve product integrity and safety. A study by the National Institute of Standards and Technology (NIST) indicated that automated packaging systems reduce packaging errors by up to 30%, thereby decreasing the likelihood of product damage during transit. Enhanced consistency in packaging minimizes the risk of contamination and meets stringent industry standards, which is particularly crucial for sectors like food and pharmaceuticals. As manufacturers continue to prioritize quality and efficiency, the adoption of automatic packaging machines will undeniably play a vital role in shaping the future of production processes.

Key Benefits of Implementing Automatic Packaging Solutions

Types of Automatic Packaging Machines and Their Applications

Automatic packaging machines play a pivotal role in modern manufacturing, enhancing efficiency and ensuring product integrity. Numerous types exist, each tailored to specific applications within various industries. For instance, horizontal flow wrappers are increasingly favored in the food sector for their ability to package products quickly while maintaining freshness. According to a report by Allied Market Research, the global packaging machinery market is projected to reach $50.8 billion by 2024, driven by the demand for automated solutions that reduce labor costs and improve production speed.

Another significant type is the vertical form-fill-seal (VFFS) machine, often employed in the packaging of granulated products like grains and snacks. These machines not only provide a high-speed solution for packing but also cater to changing market demands for smaller package sizes and eco-friendly materials. With a projected CAGR of 4.4% for VFFS machines through 2027, as noted by MarketsandMarkets, their application across diverse sectors, including pharmaceuticals and cosmetics, emphasizes their versatility and vital contribution to modern manufacturing processes.

Challenges in Integrating Automatic Packaging Systems

In the fast-paced world of modern manufacturing, the integration of automatic packaging systems presents several challenges that must be navigated effectively. One of the primary concerns is the compatibility of packaging machines with existing production lines. Manufacturers often face difficulties in ensuring that new systems work seamlessly with older equipment, leading to potential delays and increased costs. It's crucial for businesses to evaluate their current setup thoroughly before introducing automation solutions.

Tip: Conduct a comprehensive assessment of your current machinery and processes to identify any potential compatibility issues with new automatic packaging systems. This proactive approach can save both time and money in the long run.

Another challenge lies in employee training and adaptation. As packaging systems become more automated, workers may require new skills to operate and maintain these machines. Resistance to change can also surface, stemming from concerns about job security or unfamiliarity with advanced technologies.

Tip: Investing in employee training programs can address these issues. Providing hands-on workshops and continuous learning opportunities will facilitate a smoother transition to automated systems while boosting employee confidence and productivity.

Future Trends in Automatic Packaging Technology and Sustainability

The automatic packaging industry is witnessing transformative trends that are increasingly focused on sustainability and efficiency. With a market value projected to reach $2.67 billion by 2032, manufacturers are prioritizing eco-friendly practices in their packaging processes. This not only reduces environmental impact but also appeals to consumers who prefer sustainable products. Companies are exploring innovative materials and technologies, such as biodegradable plastics and energy-efficient machinery, to enhance sustainability in packaging.

To navigate this evolving landscape, businesses should consider adopting smart automation in their operations. Implementing AI-driven solutions can streamline packaging processes, minimize waste, and reduce energy consumption, contributing to long-term sustainability goals. Furthermore, companies should invest in training for their employees to become proficient in new technologies and methodologies that promote efficient packaging practices.

In addition, staying informed about market trends and consumer preferences is crucial. Regularly assessing industry reports and engaging with sustainability initiatives can provide insights into best practices. Collaborating with suppliers who prioritize sustainable practices can also create a stronger overall supply chain that aligns with environmental objectives.

Related Posts

-

What is the Impact of Best Packaging Equipment on Supply Chain Efficiency

-

Unlocking the Potential of Best Food Packaging Machines Through Comprehensive Technical Specifications and Step by Step Guidelines

-

Top Strategies for Selecting the Best Packaging Machine for Your Business

-

10 Effective Tips for Optimizing Your Packaging Equipment Strategy

-

Discover the Excellence of Chinese Manufacturing with the Best Automatic Packaging Machine

-

Partnering with China: The Future of Premium Food Packaging Solutions for Global Buyers