What is a Sachet Filling Machine and How Does it Work in Packaging Industry

In the fast-paced world of the packaging industry, efficiency and precision are paramount. One of the key innovations that has emerged to facilitate these qualities is the sachet filling machine. As packaging expert John Smith, a veteran in automated solutions, astutely notes, "A sachet filling machine not only enhances production speed but also ensures consistent quality, which is vital for maintaining consumer trust." This statement underscores the importance of such machinery in today’s market.

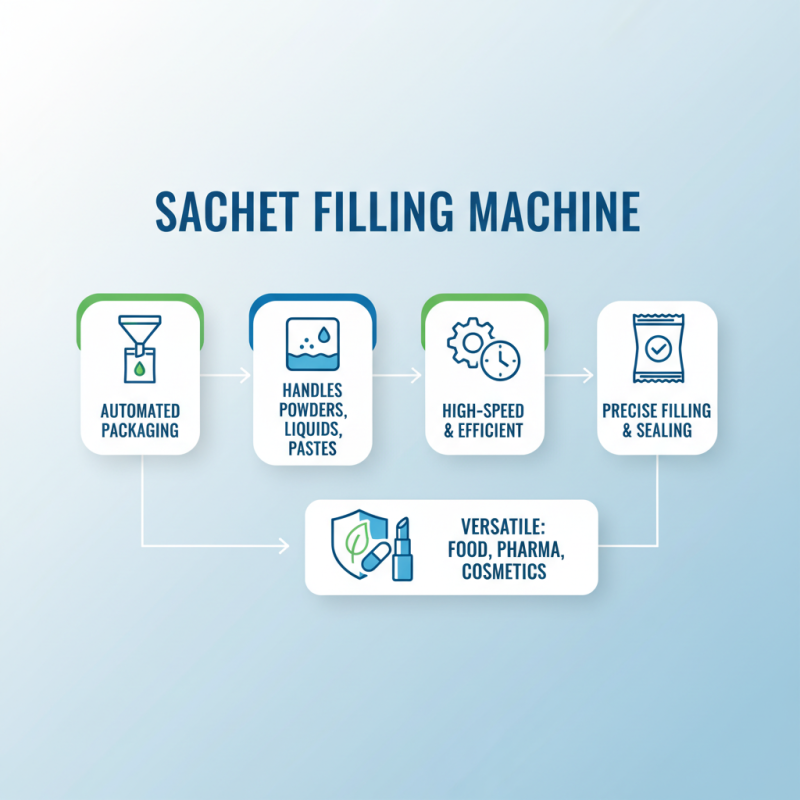

Sachet filling machines are designed to automate the process of packaging a wide variety of products, ranging from powders to liquids, all within a compact, user-friendly format. The operation of these machines hinges on advanced technology that allows for accurate filling, sealing, and cutting, resulting in efficient production workflows. As industries increasingly seek to optimize their packaging processes, understanding the functionality and advantages of sachet filling machines becomes essential for businesses aiming to stay ahead of the competition.

In this exploration of sachet filling machines, we will delve into their working mechanisms, the diverse applications they serve, and the significant impact they have on packaging efficiency. By grasping the intricacies of these machines, companies can make informed decisions that bolster their production capabilities and drive market success.

What is a Sachet Filling Machine?

A sachet filling machine is a specialized piece of equipment used in the packaging industry to automate the process of filling small pouches or sachets with a variety of products. These machines are designed to handle a range of materials, including powders, granules, liquids, and pastes, making them incredibly versatile for different sectors like food, pharmaceuticals, and cosmetics. The key advantage of utilizing sachet filling machines lies in their efficiency and precision, enabling high-speed production while maintaining consistent quality in filling and sealing.

The operation of a sachet filling machine typically involves several steps. First, empty sachets are fed into the machine, where they are opened and positioned for filling. The product is then accurately dispensed into the sachet using various filling mechanisms, such as augers for powders or pumps for liquids. After filling, the sachets undergo a sealing process to ensure product integrity and freshness, completing the packaging cycle. Modern sachet filling machines are often equipped with advanced controls and sensors to monitor the filling process, enhancing overall productivity and reducing waste throughout the packaging operation.

The Components of a Sachet Filling Machine

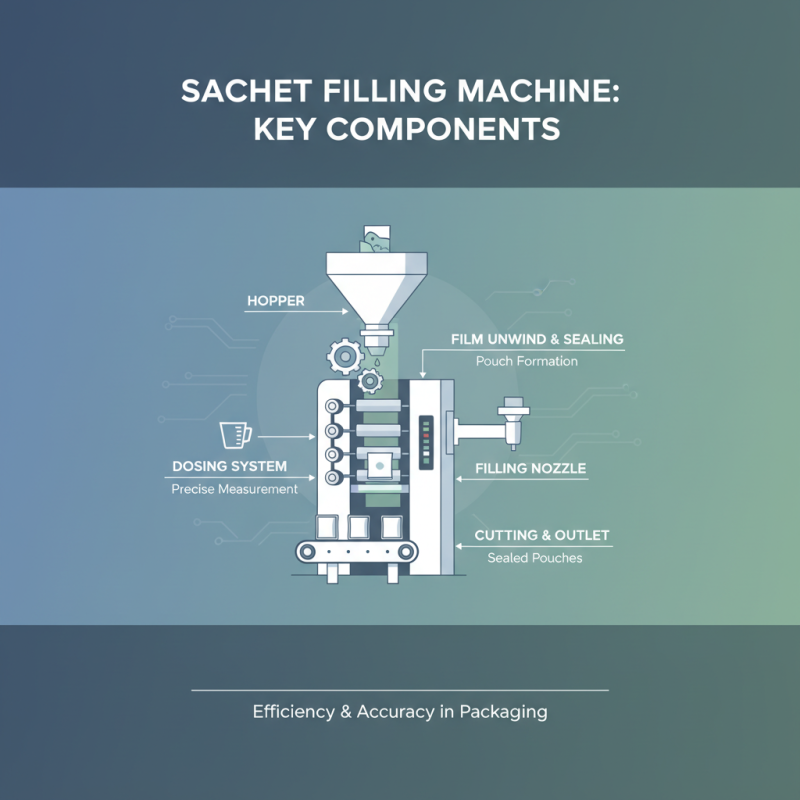

A sachet filling machine is a crucial piece of equipment in the packaging industry, designed to efficiently dispense products into small, sealed pouches. The components of a sachet filling machine work in tandem to ensure accuracy and speed in the packaging process. Key components typically include a hopper, which stores the product to be packaged, and a dosing system that precisely measures the quantity of the product for each sachet.

The machine also features a sealing mechanism, usually involving heat or ultrasonic technology, to securely close the sachets after they are filled. Conveyor systems are integrated to transport empty sachets into the filling zone while moving filled sachets to the next stage of packaging. Additionally, user interfaces allow operators to set machine parameters, monitor performance, and troubleshoot issues, ensuring a seamless operation. Overall, these components collaborate to enhance productivity, reduce waste, and maintain the quality of the packaged products.

How Sachet Filling Machines Operate: A Step-by-Step Guide

Sachet filling machines have become an integral part of the packaging industry, particularly for small quantities of products. These machines are designed to efficiently fill pre-made sachets with a range of items, from powders and liquids to granules. The operation of a sachet filling machine generally follows a systematic process. First, the machine dispenses the desired quantity of product into the sachet through precision weighing or volumetric filling systems. Industry reports indicate that the global sachet packaging market is expected to grow significantly, driven by consumer demand for single-serve products, with a CAGR of approximately 4.5% from 2021 to 2028.

Once the desired quantity is dispensed, the sachet is sealed, often using heat sealing technology, which ensures product freshness and prevents contamination. The machine typically features advanced controls for adjusting parameters such as fill volume, sealing temperature, and speed, allowing manufacturers to adapt to various product types and production needs. Additionally, the automation of these processes not only speeds up production but also reduces the chances of human error, providing higher accuracy in fill levels. According to a recent analysis, nearly 60% of manufacturers cite increased efficiency and reduced operational costs as primary benefits of employing sachet filling machines in their production lines.

Sachet Filling Machine Efficiency

This bar chart represents the average efficiency of Sachet Filling Machines in different sectors within the packaging industry. The sectors include Food & Beverage, Pharmaceuticals, Personal Care, and Household Products. Each value indicates the average output (in units per hour) that these machines can achieve.

Applications of Sachet Filling Machines in the Packaging Industry

Sachet filling machines have become essential in the packaging industry due to their efficiency and versatility. These machines are designed to pack small quantities of products into sachets, accommodating a variety of industries including food and beverage, pharmaceuticals, and cosmetics. According to a study by Smithers Pira, the global sachet packaging market is expected to reach approximately $28 billion by 2024, driven by the increasing demand for convenience and portion control in product consumption. This growth highlights the importance of sachet filling machines in enhancing packaging capabilities across different sectors.

In the food and beverage sector, sachet filling machines are widely utilized to package powdered spices, coffee, sugar, and other seasonings. The machines ensure precise dosing, helping manufacturers maintain consistent quality and reduce waste. The pharmaceutical sector also benefits from sachet packaging, with applications in single-dose medication packaging, which enhances patient compliance and safety. A report by Transparency Market Research indicates that the rising demand for compact and lightweight packaging solutions is fostering innovation in sachet filling equipment, enabling producers to meet stringent regulatory requirements while offering convenience to consumers. This adaptability is significant as businesses strive to optimize their production processes and cater to evolving market demands.

Advantages of Using Sachet Filling Machines for Packaging Solutions

Sachet filling machines play a pivotal role in the packaging industry, offering a range of advantages that enhance efficiency and product integrity. One of the primary benefits of these machines is their capability to efficiently package various products, from powders and granules to liquids, in pre-formed or custom-made sachets. This versatility allows manufacturers to cater to diverse markets and consumer preferences, ensuring that they can meet the growing demand for convenient and portable packaging solutions.

Moreover, using sachet filling machines can significantly reduce operational costs. These machines are designed for high-speed production, which means they can fill and seal sachets at a rapid pace, increasing output while minimizing labor costs. Additionally, their automated processes can lead to less material wastage, as precision filling reduces overfilling and ensures optimal use of packaging materials. This efficiency not only benefits the bottom line but also supports sustainability efforts within the industry by promoting less waste and better resource management.

Related Posts

-

Maximizing ROI on Best Bag Filling Machines Through Superior After Sales Support and Maintenance Savings

-

Unlocking Efficiency with the Best Screw Packing Machine Benefits for Global Buyers

-

The Ultimate Guide to Choosing the Right Form Fill Seal Machine for Your Business

-

Top 10 Industrial Packaging Tips to Improve Efficiency and Reduce Costs

-

What is the Impact of Best Packaging Equipment on Supply Chain Efficiency

-

Understanding the Significance of Automatic Packaging Machines in Modern Manufacturing