How to Optimize Production Efficiency with Pouch Filling Machines in Your Manufacturing Process

In today's fast-paced manufacturing landscape, the quest for operational excellence is more critical than ever. One of the most significant advancements that can lead to enhanced production efficiency is the implementation of a pouch filling machine. These versatile machines not only streamline the packaging process but also contribute to reduced waste and increased output. By automating the filling operation, manufacturers can ensure consistent quality and minimize labor costs, ultimately boosting productivity. As competition intensifies, understanding the best practices for integrating pouch filling machines into your manufacturing process becomes essential.

This guide will explore key strategies to optimize efficiency, leveraging the capabilities of pouch filling machines to achieve superior results and maintain a competitive edge in the market.

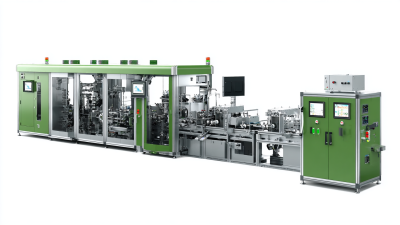

Strategies for Selecting the Right Pouch Filling Machines for Your Production Line

When selecting the right pouch filling machines for your production line, it’s crucial to consider several key factors that can significantly impact your manufacturing efficiency. First, assess the type of products you intend to package. Different machines handle various materials and formats, so choose one that accommodates your specific needs. Additionally, consider the machine's speed and output capacity, as these will directly influence your production rates.

Tips: Always look for machines with adjustable settings to adapt to varying pouch sizes. This flexibility can save time during production runs and facilitate product variety without the need for extensive retooling.

Another essential factor is the machine's ease of use and maintenance. A user-friendly interface allows your staff to operate the machinery efficiently, while a design that supports quick changeovers and easy maintenance will minimize downtime. Investing in machines with robust customer support and comprehensive warranties can also protect your operations from unexpected breakdowns.

Tips: Prioritize machines that offer comprehensive training resources for your team, as this can reduce the learning curve and enhance overall productivity in the long run.

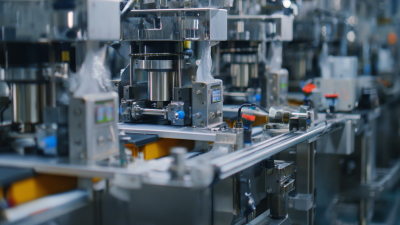

Impact of Automation in Pouch Filling Processes on Overall Operational Efficiency

Automation in pouch filling processes significantly boosts overall operational efficiency in manufacturing environments. According to a report by Grand View Research, the global pouch filling machine market is expected to grow at a CAGR of 5.2% from 2021 to 2028, reflecting the increasing adoption of automation technologies. These machines not only enhance speed but also minimize human error, which can lead to less waste and higher quality control. For instance, automated systems can fill up to 200 pouches per minute, compared to the 40-60 pouches handled manually, thereby reducing labor costs and increasing throughput.

Tips for optimizing your pouch filling process include investing in adjustable filling nozzles to accommodate various product viscosities, ensuring minimal downtime during changeovers. Additionally, implementing a predictive maintenance strategy can further enhance performance by addressing potential issues before they result in costly disruptions. Integrating data analytics tools into the pouch filling process allows manufacturers to monitor performance metrics in real time, leading to informed decision-making and continuous improvement.

Furthermore, the integration of robotics in pouch filling machines provides consistent alignment and precision, which is critical for maintaining packaging integrity. As highlighted by MarketsandMarkets, nearly 70% of manufacturers report an increase in production efficiency after transitioning to automated systems. By focusing on automation, manufacturers can leverage these advancements to streamline operations, reduce costs, and ultimately, respond more quickly to market demand.

How to Optimize Production Efficiency with Pouch Filling Machines in Your Manufacturing Process - Impact of Automation in Pouch Filling Processes on Overall Operational Efficiency

| Parameter | Pre-Automation | Post-Automation | Improvement (%) |

|---|---|---|---|

| Filling Speed (pouches/min) | 30 | 75 | 150% |

| Labor Cost per Hour ($) | 25 | 10 | 60% |

| Product Waste (% of total) | 5 | 2 | 60% |

| Overall Downtime (% of total time) | 20 | 5 | 75% |

| Total Production Output (units/week) | 1680 | 4200 | 150% |

Key Performance Indicators (KPIs) to Measure Pouch Filling Machine Effectiveness

To optimize production efficiency with pouch filling machines, it is essential to track and analyze specific Key Performance Indicators (KPIs). These KPIs serve as measurable values that indicate how well the machines and processes are performing. One critical KPI is the filling accuracy, which measures the precision of the volume filled per pouch. High accuracy levels minimize product waste and enhance customer satisfaction, ensuring that every package meets quality standards.

Another important KPI is the machine uptime, which reflects the amount of time the pouch filling machines are operational versus downtime caused by maintenance or other issues. Maximizing uptime ensures a steady production flow and helps in meeting demand without unnecessary delays. Lastly, measuring the output rate—number of pouches filled per hour—provides insights into production speed and efficiency. By regularly reviewing these KPIs, manufacturers can identify bottlenecks or inefficiencies in their operations and implement data-driven adjustments that enhance overall productivity.

Latest Technological Advancements in Pouch Filling Machines for Enhanced Productivity

Recent advancements in pouch filling machines have significantly transformed the manufacturing landscape, particularly in achieving higher productivity and efficiency. The liquid filling machine market is projected to grow substantially, with estimates suggesting a valuation exceeding $6 billion by 2025. This growth is propelled by increasing consumer demand for convenience packaging, alongside technological innovations in automation. Segmenting the market by functionality, fully automatic filling machines currently dominate, accounting for over 60% of the market share due to their ability to enhance speed and reduce labor costs.

Moreover, the filling types employed also contribute to efficiency gains. Vacuum filling technology is notable for its capability to maintain product integrity, especially in sensitive liquids, while weighing and volumetric filling systems offer precision that meets the stringent requirements of various industries. With the rise of smart manufacturing, integrating IoT technology into pouch filling machines can lead to real-time monitoring and predictive maintenance, further optimizing production processes.

**Tips for Maximizing Productivity:**

- Ensure regular maintenance of filling machines to prevent downtime.

- Consider investing in training for operators to skillfully handle both automatic and semi-automatic machines.

- Explore upgrading to multi-functional filling machines that can accommodate various pouch types and fill methods to adapt to changing production needs.

Cost-Benefit Analysis of Upgrading to High-Speed Pouch Filling Systems

Upgrading to high-speed pouch filling systems can provide significant economic advantages for manufacturing processes. By investing in modern pouch filling machines, companies can achieve increased throughput, which directly correlates with higher productivity. The initial investment may appear substantial, but a closer examination reveals the long-term savings associated with reduced labor costs, lower waste levels, and elevated output quality. High-speed filling systems offer enhanced automation and precision, minimizing the risks of human error and ensuring that each pouch is filled accurately and efficiently.

Furthermore, conducting a cost-benefit analysis highlights the potential return on investment (ROI) derived from these upgrades. Beyond the improved efficiency, high-speed systems can adapt to various pouch sizes and materials, making them versatile for different product lines. This adaptability not only helps streamline operations but also allows manufacturers to respond swiftly to market demands. Ultimately, the switch to high-speed pouch filling machines can lead to increased market competitiveness, making it a sensible strategy for companies aiming to enhance their production efficiency and bottom line.

Related Posts

-

Exploring the Future of Pouch Filling Machines in 2025 and How to Optimize Your Production Process

-

What is the Impact of Best Packaging Equipment on Supply Chain Efficiency

-

How to Choose the Right Filling Machine for Your Business Needs

-

Navigating Global Trade: How to Obtain Export and Import Certifications for the Best Food Packaging Machine

-

Unveiling the Advantages of Innovative Flexible Packaging Solutions for Modern Businesses

-

Unlocking Efficiency with the Best Screw Packing Machine Benefits for Global Buyers