The Future of Liquid Packaging Machines: Innovations Driving Efficiency and Sustainability in 2025

As the global liquid packaging market continues to expand, expected to reach $350 billion by 2025, the evolution of liquid packaging machines is crucial for businesses aiming to enhance efficiency and sustainability. Recent reports suggest that innovative technologies, such as automation and smart packaging solutions, are not only streamlining production processes but also significantly reducing waste and energy consumption.

For instance, companies implementing advanced liquid packaging machines have reported a 30% increase in operational efficiency while cutting down on carbon emissions. As consumer demand for environmentally friendly packaging solutions rises, the integration of sustainable practices in liquid packaging machinery will be indispensable.

This blog explores the driving innovations in the industry, focusing on how these advancements are shaping the future of liquid packaging solutions in 2025 and beyond.

The Rise of Eco-Friendly Materials in Liquid Packaging by 2025

In the pursuit of sustainability, the liquid packaging industry is undergoing a significant transformation with the rise of eco-friendly materials. By 2025, manufacturers are increasingly focusing on innovative packaging solutions that minimize environmental impact while maintaining efficiency. The introduction of biodegradable and recyclable materials is set to enhance the lifecycle of packaging and contribute to a circular economy. These advancements not only align with consumer demand for greener products but also comply with an evolving regulatory landscape focused on sustainability.

The global market for gable top liquid cartons is projected to grow considerably, indicating a robust demand for sustainable packaging options. Valued at approximately $10.17 billion in 2025, the sector illustrates a shift towards eco-conscious choices. As brands explore bulk liquid transport packaging, the emphasis on safety and sustainability will drive innovations that reduce waste and improve product integrity. Initiatives like Global Recycling Day in 2025 will further highlight the industry's commitment to superior packaging solutions, recognizing those that excel in embracing both efficiency and environmental responsibility.

The Future of Liquid Packaging Machines: Innovations Driving Efficiency and Sustainability in 2025

| Dimension | Value in 2025 |

|---|---|

| Percentage of Eco-Friendly Materials Used | 70% |

| Average Machine Efficiency Improvement | 30% |

| Reduction in Plastic Use | 40% |

| Investment in Sustainable Technologies | $1.5 Billion |

| Percentage of Biodegradable Packaging Solutions | 50% |

| Increase in Recyclability of Packaging | 60% |

| Consumer Preference for Eco-Friendly Packaging | 85% |

Smart Liquid Packaging Technologies: Automation and Data Integration

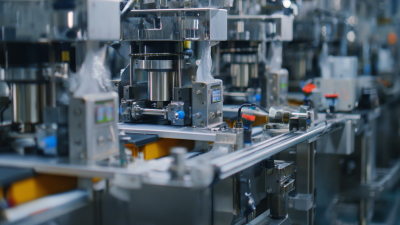

As we look toward 2025, the landscape of liquid packaging machines is undergoing a transformative shift powered by smart technologies. Automation stands at the forefront of this evolution, enhancing operational efficiency and minimizing human error. By incorporating advanced robotics and automated workflows, manufacturers are able to streamline production lines, reduce downtime, and significantly accelerate packaging processes. This increase in efficiency not only meets the rising demand for packaged liquids but also lowers operational costs, making it a win-win for businesses.

Equally important is the integration of data-driven solutions into liquid packaging systems. By leveraging the Internet of Things (IoT) and big data analytics, companies can gain real-time insights into their packaging operations. This data integration allows for predictive maintenance, ensuring that machines operate at peak performance and reducing the risk of unexpected failures. Furthermore, it facilitates the optimization of supply chain logistics, enabling businesses to respond swiftly to market changes while adhering to sustainability goals. In an era where efficiency and environmental responsibility are paramount, the fusion of smart technologies in liquid packaging stands to reshape the industry significantly.

The Future of Liquid Packaging Machines: Innovations Driving Efficiency and Sustainability in 2025

Impact of Government Regulations on Sustainable Packaging Solutions

The drive for sustainable packaging solutions is being significantly influenced by government regulations aimed at reducing plastic waste and encouraging recycling. As single-use plastics face bans in numerous regions, the demand for eco-friendly packaging alternatives is rapidly increasing. The corrugated bulk container market has exceeded $14.2 billion in 2023, with an anticipated compound annual growth rate (CAGR) of approximately 5% from 2024 to 2032, reflecting the growing consumer preference for sustainable packaging options.

Similarly, the recycled materials packaging market, valued at $189.9 billion in 2024, is projected to see a CAGR of over 5.4% from 2025 to 2034. This surge is largely driven by heightened consumer awareness regarding sustainability. The shift towards reusability and recycling initiatives has compelled companies to invest in packaging solutions that utilize recyclable and biodegradable materials. With the projected growth of these markets, industry players are becoming increasingly innovative in their approaches to meet both regulatory demands and the evolving expectations of environmentally conscious consumers.

Case Studies: Brands Leading the Way in Efficient Liquid Packaging Innovations

In 2025, the landscape of liquid packaging is being transformed by several innovative brands that prioritize both efficiency and sustainability. Notable among these trailblazers is a popular beverage company that has adopted bio-based packaging materials derived from renewable resources. This shift not only reduces the carbon footprint but also enhances the shelf life of their products. By investing in advanced technology that ensures packaging is not only lightweight but also fully recyclable, the brand exemplifies how sustainability can coexist with operational efficiency.

Another leading brand making waves in liquid packaging is an innovative food producer that has introduced a unique filling technology, drastically minimizing product waste during the packaging process. Utilizing a smart, automated system, they have achieved a higher throughput while maintaining product integrity. This technology not only streamlines their production line but also contributes to significant resource savings. These case studies illustrate the critical role that forward-thinking companies play in shaping a more sustainable future in liquid packaging, setting an example for others to follow in 2025 and beyond.

Future-Proofing the Supply Chain: Trends in Liquid Packaging Machinery

The landscape of liquid packaging machinery is evolving rapidly as companies seek to enhance efficiency while embracing sustainability. According to a report by Smithers Pira, the global liquid packaging market is projected to reach $456 billion by 2025, driven largely by innovations that streamline production processes. A significant trend is the integration of automation and smart technology in packaging machines, which can reduce labor costs by up to 30% and minimize human error. This shift not only boosts operational efficiency but also aligns with the growing demand for faster production capabilities.

Moreover, sustainability is becoming a critical focus in liquid packaging machinery. Research from the Sustainable Packaging Coalition indicates that approximately 68% of consumers prefer brands that use eco-friendly packaging. As a response, manufacturers are increasingly adopting machines designed to work with recyclable materials and biodegradable options. Enhanced design features, such as reduced energy consumption and waste, are not only beneficial for the environment but also promise significant cost savings. With these innovations, liquid packaging machinery is not just about filling and capping; it's about creating a sustainable future while ensuring a robust supply chain that meets both consumer demands and regulatory standards.

Related Posts

-

How to Choose the Best Liquid Packaging Machine: Trends Shaping the Industry by 2025

-

The Ultimate Guide to Choosing the Right Form Fill Seal Machine for Your Business

-

Exploring the Future of Pouch Filling Machines in 2025 and How to Optimize Your Production Process

-

Unleashing the Power of Best Automatic Packaging Machines from China's Leading Manufacturers

-

Mastering Best Industrial Packaging Specifications and Tips for Optimal Use

-

Understanding the Advantages of the Best Vacuum Packing Machine for Your Business