The Future of Intelligent Packaging Line Automation: Transforming Global Supply Chains

As industries worldwide continue to evolve, the future of packaging line automation is at the forefront of transforming global supply chains. According to a recent report by MarketsandMarkets, the intelligent packaging market is projected to reach $31.4 billion by 2026, growing at a CAGR of 10.5% from 2021. This surge is driven by the increasing demand for automation to enhance efficiency, reduce operational costs, and improve product traceability.

The integration of advanced technologies such as IoT, AI, and robotics in packaging line automation is set to revolutionize the way products are packed and delivered, enabling companies to respond swiftly to market demands. As businesses seek to optimize their supply chains and ensure seamless operations, understanding the intricacies of intelligent packaging line automation becomes crucial to staying competitive in an increasingly complex marketplace.

The Rise of Intelligent Packaging: Key Statistics Shaping the Future of Supply Chains

The adoption of intelligent packaging is on the rise, with a recent report from Research and Markets projecting that the global intelligent packaging market will reach $42.4 billion by 2027, growing at a CAGR of 5.8% from 2020. This growth is driven by innovations in technology such as IoT integration, which allows for real-time tracking and enhanced product safety. In a world where consumer expectations are constantly evolving, intelligent packaging not only improves supply chain efficiency but also enhances the customer experience through features such as QR codes and smart labels.

When implementing intelligent packaging solutions, companies should consider the following tips: First, invest in robust data analytics to gain insights from consumer interactions, enabling better decision-making. Second, prioritize sustainability by choosing eco-friendly packaging materials that meet both regulatory requirements and consumer demand for greener alternatives. Lastly, collaborate with technology partners who specialize in automation and IoT to seamlessly integrate these systems into existing supply chains.

Furthermore, statistics reveal that 73% of consumers prefer brands that offer transparent information about the products they purchase. This growing demand for transparency showcases how intelligent packaging plays a vital role in building customer trust and loyalty. As brands innovate and automate their packaging lines, they not only streamline their operations but also position themselves for a more resilient and responsive supply chain.

Automation Technologies Revolutionizing Packaging Efficiency in Global Markets

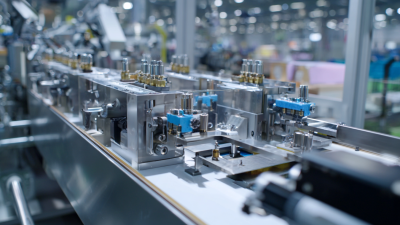

In today’s fast-paced global markets, the demand for efficiency in packaging is more crucial than ever. Automation technologies are at the forefront, revolutionizing how products are packaged and distributed. With advancements in robotics, artificial intelligence, and IoT, businesses can streamline their packaging lines, reducing labor costs while increasing speed and accuracy. Automated systems can adapt to various product types and sizes, making it easier for companies to respond to changing market demands without extensive downtime.

Moreover, intelligent packaging line automation enhances quality control, ensuring that products are packaged consistently and meet regulatory standards. Smart sensors and data analytics provide real-time insights, allowing businesses to monitor their packaging processes and identify areas for improvement. This proactive approach not only minimizes waste but also enhances sustainability efforts within the supply chain, aligning with the growing consumer preference for eco-friendly practices. As these technologies continue to evolve, they will undoubtedly play a pivotal role in shaping the future of packaging and logistics in the global economy.

The Future of Intelligent Packaging Line Automation: Transforming Global Supply Chains

| Technology | Impact on Efficiency (%) | Investment Cost (USD) | Return on Investment (ROI) (Years) | Adoption Rate (%) |

|---|---|---|---|---|

| Robotic Process Automation | 30 | 150,000 | 2 | 50 |

| IoT Enabled Packaging | 25 | 200,000 | 3 | 40 |

| AI-Powered Quality Control | 40 | 250,000 | 4 | 35 |

| Machine Learning for Predictive Maintenance | 33 | 180,000 | 2.5 | 45 |

| Automated Supply Chain Management | 50 | 300,000 | 3.5 | 60 |

The Environmental Impact of Intelligent Packaging: A Data-Driven Perspective

The environmental impact of intelligent packaging is increasingly becoming a topic of discussion in global supply chains. By embracing data-driven strategies, companies can significantly minimize waste and enhance sustainability. Intelligent packaging solutions, equipped with sensors and real-time analytics, allow for better tracking of products throughout their lifecycle. This technology not only reduces spoilage and overproduction but also encourages recycling by providing consumers with clear disposal instructions through smart labels.

Moreover, intelligent packaging can optimize the use of materials, leading to a more efficient supply chain. By analyzing data on consumer behavior and environmental conditions, businesses can tailor their packaging to meet specific needs, thereby reducing excess material usage. This efficiency not only cuts costs but also helps lower the carbon footprint associated with production, transportation, and disposal. As companies strive for more sustainable practices, leveraging intelligent packaging is becoming essential in steering global supply chains towards a greener future.

Cost-Benefit Analysis: Investing in Intelligent Packaging for Long-term Gains

In today's fast-paced market, intelligent packaging line automation stands out as a pivotal investment for companies aiming to enhance efficiency in their supply chains. A cost-benefit analysis reveals that while the initial setup costs may seem daunting, the long-term gains far outweigh these expenses. Automating packaging processes not only reduces labor costs but also minimizes human error, which can lead to significant savings in the long run. Moreover, the ability to track products in real-time provides companies with critical data that can be used to optimize logistics and inventory management.

Tip: When considering an investment in intelligent packaging, start with a pilot program. This allows you to evaluate the technology's performance and its impact on your specific operations before making a full-scale commitment.

Another aspect to consider is the sustainability benefits of automated packaging systems. By implementing eco-friendly materials and reducing waste through precision in packaging, companies can improve their brand image while also cutting costs associated with excess material use.

Tip: Collaborate with suppliers who prioritize sustainability. This not only enhances your packaging solutions but also strengthens your overall supply chain efficiency.

The Future of Intelligent Packaging Line Automation

This chart illustrates the cost-benefit analysis of investing in intelligent packaging line automation. The data represents the estimated financial impact across various dimensions, highlighting the initial investment and the expected returns over the short and long term.

Emerging Trends in Consumer Preferences Driving Intelligent Packaging Innovations

The evolution of consumer preferences is dramatically reshaping the landscape of packaging innovations. As today's consumers become more environmentally conscious and tech-savvy, they demand packaging solutions that not only protect their products but also align with their values. Intelligent packaging—encompassing smart labels, QR codes, and even integrated sensors—addresses these demands by enhancing transparency and interactivity. Manufacturers are now prioritizing sustainable materials and designs that minimize waste, responding to the increasing pressure from consumers who seek eco-friendly options.

Moreover, the rise of e-commerce has propelled the need for packaging that ensures product integrity throughout complex supply chains. Intelligent packaging technologies are being developed to provide real-time tracking and condition monitoring, allowing consumers to engage with products in a more informed manner. This shift towards smart, interactive packaging reflects a broader trend where companies must adapt to consumer preferences that value not only the functionality of packaging but also its storytelling capability. By integrating technology into packaging, businesses can foster stronger connections with their customers, enhance the overall user experience, and drive brand loyalty in an increasingly competitive market.

Related Posts

-

What Makes the Best Food Packing Machine Essential for Modern Food Industry

-

Unleashing the Power of Best Automatic Packaging Machines from China's Leading Manufacturers

-

Discover the Excellence of Chinese Manufacturing with the Best Automatic Packaging Machine

-

The Ultimate Guide to Choosing the Right Form Fill Seal Machine for Your Business

-

10 Effective Tips for Optimizing Your Packaging Equipment Strategy

-

Exploring the Future of Best Flexible Packaging Trends and Market Insights for 2025