Top 10 Tips for Choosing the Best Automated Packaging Machine for Your Business

When it comes to optimizing efficiency and maintaining competitiveness in the fast-paced world of manufacturing and distribution, choosing the right automated packaging machine is paramount. Experts in the field emphasize not just the importance of these machines, but also the need for careful consideration when selecting the right one for specific business needs. As packaging industry expert Dr. Emily Carter states, “The right automated packaging machine can significantly enhance productivity, reduce waste, and improve product presentation.”

In today’s market, where consumer expectations are constantly evolving, businesses must equip themselves with the best technology available. Automated packaging machines play a crucial role in streamlining operations while ensuring that the packaging process is consistent and reliable. Understanding what features and capabilities to look for can make the difference between success and frustration.

This article aims to provide essential insights into the top 10 tips for choosing the best automated packaging machine tailored to your business. By leveraging these guidelines, entrepreneurs can navigate the complexities of the decision-making process and ultimately enhance their packaging operations.

Understanding Your Packaging Needs and Production Goals

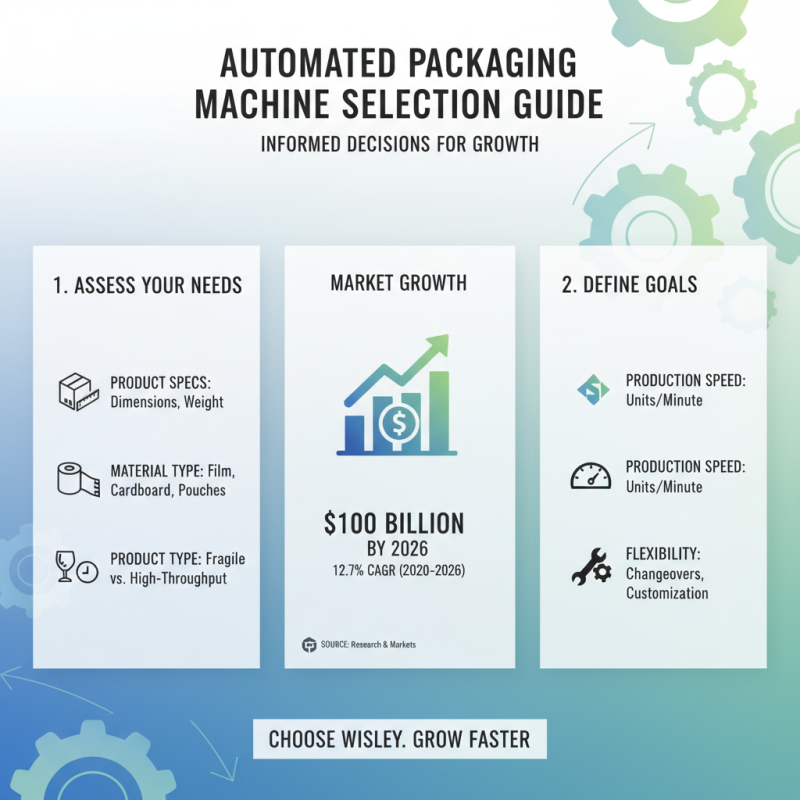

When selecting the right automated packaging machine for your business, a thorough understanding of your packaging needs and production goals is crucial. The global automated packaging market is expected to reach $100 billion by 2026, growing at a CAGR of 12.7% from 2020 to 2026, according to a report by Research and Markets. This significant growth underscores the importance of making informed decisions based on specific requirements. First, assess your product dimensions, weight, and packaging material. Different products demand unique packaging solutions; for instance, fragile items require more protective packaging, while high-throughput environments may prioritize speed over flexibility.

Moreover, you should evaluate your production goals. Are you aiming for increased throughput, reduced labor costs, or enhanced product consistency? A study by PMMI indicates that companies adopting automated solutions can increase productivity by up to 30%. Your output needs will directly influence the type of packaging machine you choose, whether it is a case packer, a shrink wrapper, or an automatic carton sealer. Understanding these factors will help you to select a machine that aligns with your production demands while maximizing efficiency and minimizing waste, ensuring that your investment in automation pays off in the long run.

Evaluating Different Types of Automated Packaging Machines

When evaluating different types of automated packaging machines, it is essential to consider the specific needs of your business. Start by analyzing the nature of the products you intend to package. For instance, products that are fragile may require a machine with gentle handling capabilities, while bulkier items might necessitate equipment designed for high-speed operations. Look into machines that offer versatility in packaging formats, as this allows for adaptations based on varying product sizes or seasonal shifts in demand.

Another crucial aspect to consider is the level of automation you require. Options range from semi-automated machines that require manual input for certain tasks to fully automated systems that handle every aspect of the packaging process with minimal human intervention. Assessing your workforce's skills and availability can help in making this decision. Additionally, the technology behind these machines, such as their integration with existing production lines and their maintenance requirements, plays a significant role in ensuring seamless operations. Prioritizing machines that offer user-friendly interfaces will facilitate easier training for your staff, thus enhancing overall efficiency in your packing processes.

Top 10 Tips for Choosing the Best Automated Packaging Machine

Assessing Budget and Cost-Effectiveness of Packaging Solutions

When selecting an automated packaging machine, assessing the budget and cost-effectiveness of various options is crucial for business sustainability. According to a report by Smithers Pira, the global market for packaging machinery is projected to reach $45 billion by 2025, illustrating the growing need for efficient and economical solutions. Companies must evaluate not just the initial purchase cost of the machinery, but also the total cost of ownership, which includes maintenance, operation, and potential downtimes. A well-planned investment in automated packaging can lead to a significant reduction in labor costs, with some reports suggesting savings of up to 30-40% in labor expenditures.

In addition to direct cost considerations, businesses should analyze the return on investment (ROI) associated with automated packaging solutions. Research from the Association for Packaging and Processing Technologies indicates that companies that adopt advanced packaging technology can expect an average ROI of 15-25% within the first year of operation. Metrics such as throughput efficiency, waste reduction, and improved product shelf life are essential for calculating long-term savings. By focusing on these financial metrics, businesses can make informed decisions that enhance productivity and profitability while ensuring their packaging processes remain competitive in the rapidly evolving market.

Researching Suppliers and Looking for Customer Reviews

When considering the purchase of an automated packaging machine for your business, thoroughly researching suppliers is crucial. Begin by identifying potential manufacturers that specialize in automated packaging solutions tailored to your industry needs. Look for suppliers who have a proven track record and significant experience in the field, as established manufacturers are more likely to produce reliable and high-quality machinery. Evaluate their product range and see if they offer customization options that could suit your specific requirements.

Customer reviews serve as a powerful tool in your decision-making process. Take the time to read through feedback from businesses that have previously used the machines you are considering. Pay attention to common themes in their experiences, such as ease of use, machine reliability, and the level of customer service provided by the supplier. Look for reviews that highlight not only positive aspects but also any issues encountered, as this will provide a more balanced view. Engaging with existing customers, perhaps through online forums or social media, can also yield insights that inform your choice and help you avoid potential pitfalls.

Considering Machine Size and Footprint for Your Workspace

When selecting an automated packaging machine for your business, considering the machine size and footprint is crucial for optimizing your workspace efficiency. First, you need to evaluate the available space in your facility. Measure the area where the machine will be placed to ensure you have adequate room not only for the equipment itself but also for its operation and maintenance. A compact machine can be a suitable choice if floor space is limited, allowing you to maintain workflow without overcrowding.

Another key aspect is the layout of your production line. Think about how the packaging machine will integrate with other equipment and processes. An effective layout minimizes unnecessary movement and enhances productivity. Choose a machine that complements your existing workflow, ensuring smooth transitions between packing and other stages. Additionally, remember to leave extra space for any future expansions or changes in your packaging needs, as flexibility can be an essential factor in the long-term success of your operations.

When assessing machine features, prioritize those that can accommodate your packaging volume and dimensions while fitting within your designated area. Opting for customizable or modular machines can provide adaptability, allowing you to easily scale up or adjust as your business grows. Ultimately, finding the right balance between size, functionality, and space constraints will help streamline your packaging process, contributing to optimal operational efficiency.

Related Posts

-

Discover the Excellence of Chinese Manufacturing with the Best Automatic Packaging Machine

-

10 Effective Tips for Optimizing Your Packaging Equipment Strategy

-

Understanding the Significance of Automatic Packaging Machines in Modern Manufacturing

-

How to Choose the Right Packaging Equipment for Your Business Needs

-

Unlocking the Potential of Best Food Packaging Machines Through Comprehensive Technical Specifications and Step by Step Guidelines

-

What Makes the Best Food Packing Machine Essential for Modern Food Industry