Understanding the Advantages of the Best Vacuum Packing Machine for Your Business

In today's competitive business landscape, the efficient preservation and packaging of products are paramount, and a vacuum packing machine has emerged as a game-changer across various industries. According to a report by Grand View Research, the global vacuum packaging market is expected to reach USD 30.98 billion by 2025, driven by increasing consumer demand for convenience and extended shelf life of food products.

Benefits of Investing in a High-Quality Vacuum Packing Machine for Your Business

Investing in a high-quality vacuum packing machine can transform the way your business operates, providing numerous advantages that directly enhance efficiency and product longevity. According to a report by Research and Markets, the global vacuum packaging market is projected to reach $42.4 billion by 2027, driven by the growing demand for preserved food and extended shelf life. A reliable vacuum packing machine aids in significantly reducing food waste and spoilage, which can be crucial for businesses operating in the food industry. With up to 50% less spoilage, companies can optimize their inventory management and improve profit margins.

Moreover, advanced vacuum packing machines offer tailored packaging solutions that adapt to various product types, from perishable goods to industrial components. A study by the Packaging Machinery Manufacturers Institute (PMMI) indicates that nearly 70% of food manufacturers consider vacuum packaging essential for maintaining quality. By investing in a high-quality machine, businesses not only ensure product freshness but also cater to customer preferences for sustainable and eco-friendly packaging. Ultimately, these machines enhance brand reputation and foster customer loyalty by consistently delivering high-quality products.

Understanding the Advantages of the Best Vacuum Packing Machine for Your Business

| Feature | Description | Benefits |

|---|---|---|

| Efficiency | Automates the packaging process | Saves time and labor costs |

| Shelf Life Extension | Removes air to prevent oxidation | Reduces spoilage and waste |

| Space Efficiency | Compact packaging design | Maximizes storage space |

| Versatility | Suitable for various food types | Enhances product offerings |

| Cost Savings | Less food spoilage and waste | Improves profitability |

| Quality Preservation | Maintains texture and flavor | Enhances customer satisfaction |

Key Features to Look for in the Best Vacuum Packing Machines

When choosing the best vacuum packing machine for your business, it is essential to focus on key features that directly impact efficiency and product quality. According to a report by Mintel, the global vacuum packaging market is expected to reach $30 billion by 2026, underscoring the growing importance of this technology in various industries. Start by considering the machine's sealing capabilities; professional-grade vacuum sealers should have adjustable settings for different bag thicknesses, allowing for optimal performance with various products.

Another crucial feature is the speed and efficiency of the vacuuming process. A high-quality machine should be able to complete the vacuum sealing in under 30 seconds, which can significantly enhance productivity in busy environments. Research from Technavio indicates that machines with enhanced technology, such as double sealing and intelligent control systems, have seen a 20% increase in usability among businesses.

Tips: Always pay attention to the machine's warranty and customer support. A robust warranty indicates manufacturer confidence in their equipment, while reliable customer support helps you quickly resolve issues. Finally, consider the machine's compatibility with biodegradable bags, as sustainability is increasingly becoming a priority for consumers and businesses alike.

Understanding the Advantages of the Best Vacuum Packing Machine for Your Business

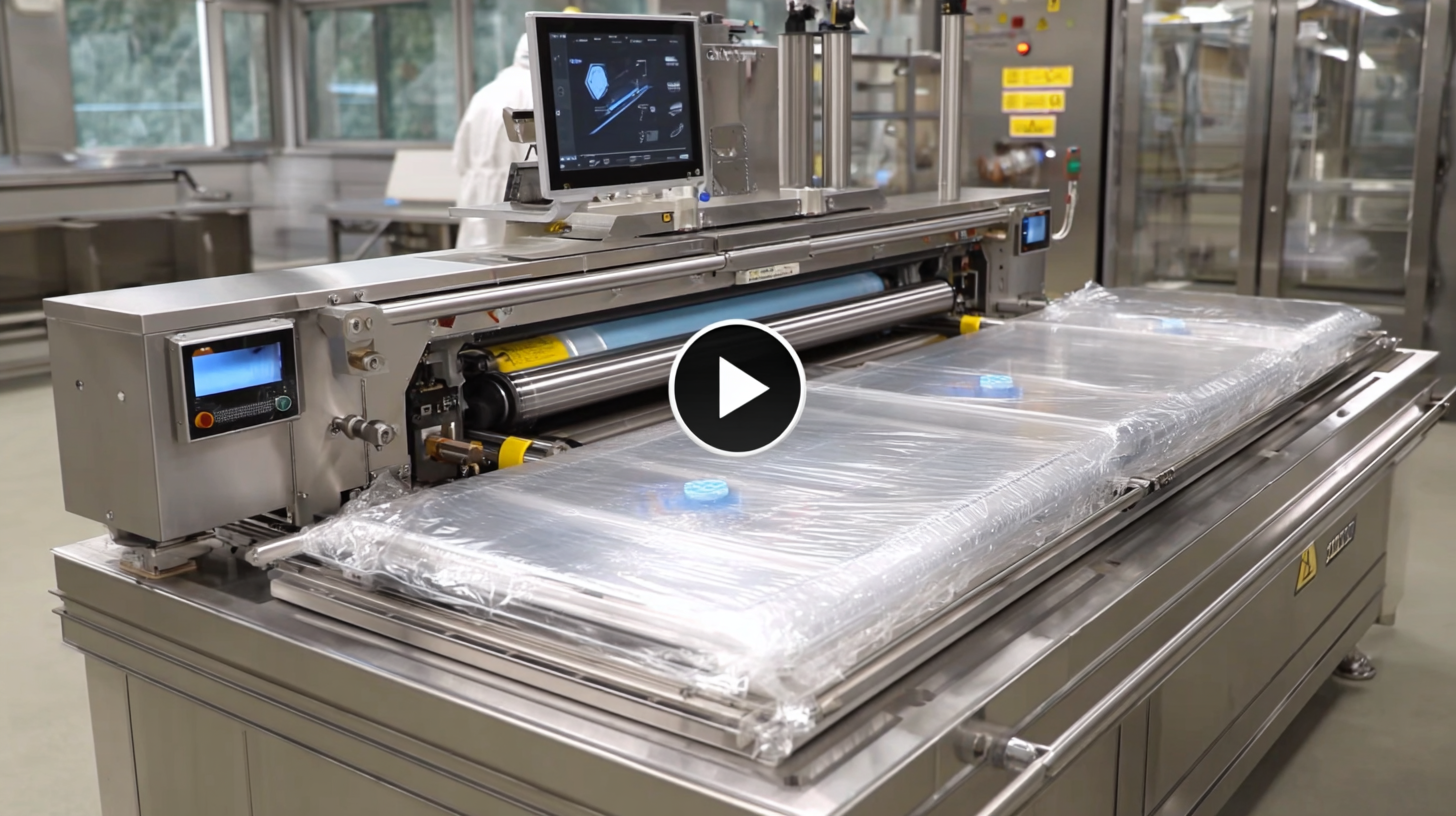

This chart illustrates the key advantages of vacuum packing machines that businesses should consider. Each bar represents the percentage advantage these features provide, showcasing their importance in improving operational efficiency and product quality.

Cost Savings and Increased Efficiency with Vacuum Packing Solutions

Vacuum packing machines are becoming increasingly essential for businesses looking to optimize their operations through cost savings and efficiency. According to a report by the Food Packaging Association, over 70% of food-related businesses have reported reduced waste due to improved shelf life, thanks to vacuum packaging. This method not only minimizes spoilage but also extends the freshness of products, allowing companies to manage inventory more effectively and ultimately reduce costs associated with spoilage.

Moreover, the efficiency of vacuum packing solutions is evident in their ability to streamline the packaging process. The Association for Packaging and Processing Technologies indicates that implementing a vacuum packing system can increase production speed by up to 50%. Businesses benefit from faster packaging times, which can lead to higher output and greater customer satisfaction. As consumer demand for quick delivery increases, the efficiency offered by vacuum packing becomes a crucial competitive advantage in the market. Investing in high-quality vacuum packing machines can, therefore, result in significant savings and improved operational efficiency for businesses across various sectors.

How Vacuum Packing Enhances Product Freshness and Shelf Life

Vacuum packing has emerged as a crucial technology for businesses aiming to enhance product freshness and extend shelf life. By removing air from packaging, vacuum sealing significantly reduces the oxidation process, which is a leading cause of spoilage. According to a report by the Food and Drug Administration (FDA), vacuum-sealed products can last up to 5 times longer than those packaged conventionally, making it an invaluable solution for food manufacturers and distributors alike.

Tips:

- Invest in high-quality vacuum packing machines designed for your specific needs to ensure optimal sealing and product integrity.

- Regularly monitor the vacuum pressure to maintain ideal packaging conditions, as inconsistent levels can compromise freshness.

Tips:

- Use vacuum packing for a variety of perishable products, from meats to vegetables, to optimize your inventory management.

- Train staff on proper vacuum sealing techniques for consistent results and to minimize the risk of spoilage.

Comparing Different Models: Choosing the Right Vacuum Packing Machine for Your Needs

When it comes to selecting the right vacuum packing machine for your business, understanding the different models available is crucial. With a variety of options on the market, each designed to cater to specific packaging needs, evaluating their features can significantly impact your operational efficiency. Consider factors such as the machine’s size, suction power, and sealing capabilities. Models with adjustable settings can offer versatility, allowing you to customize the vacuum process based on the products you handle.

Tip: Before making a purchase, assess the volume of goods you intend to package. If your business requires high throughput, opt for a commercial-grade machine that can handle larger batches without compromising on quality.

Additionally, it's essential to look into the durability of the vacuum packing machine. A well-constructed model will not only last longer but also minimize maintenance costs. Research customer reviews and reliability ratings to gain insights into the performance of different brands.

Tip: Consider machines that offer a warranty or customer support services — this can be a lifesaver if you encounter any issues down the line. Choosing the right model tailored to your specific needs can enhance operational efficiency and ultimately contribute to your business's bottom line.