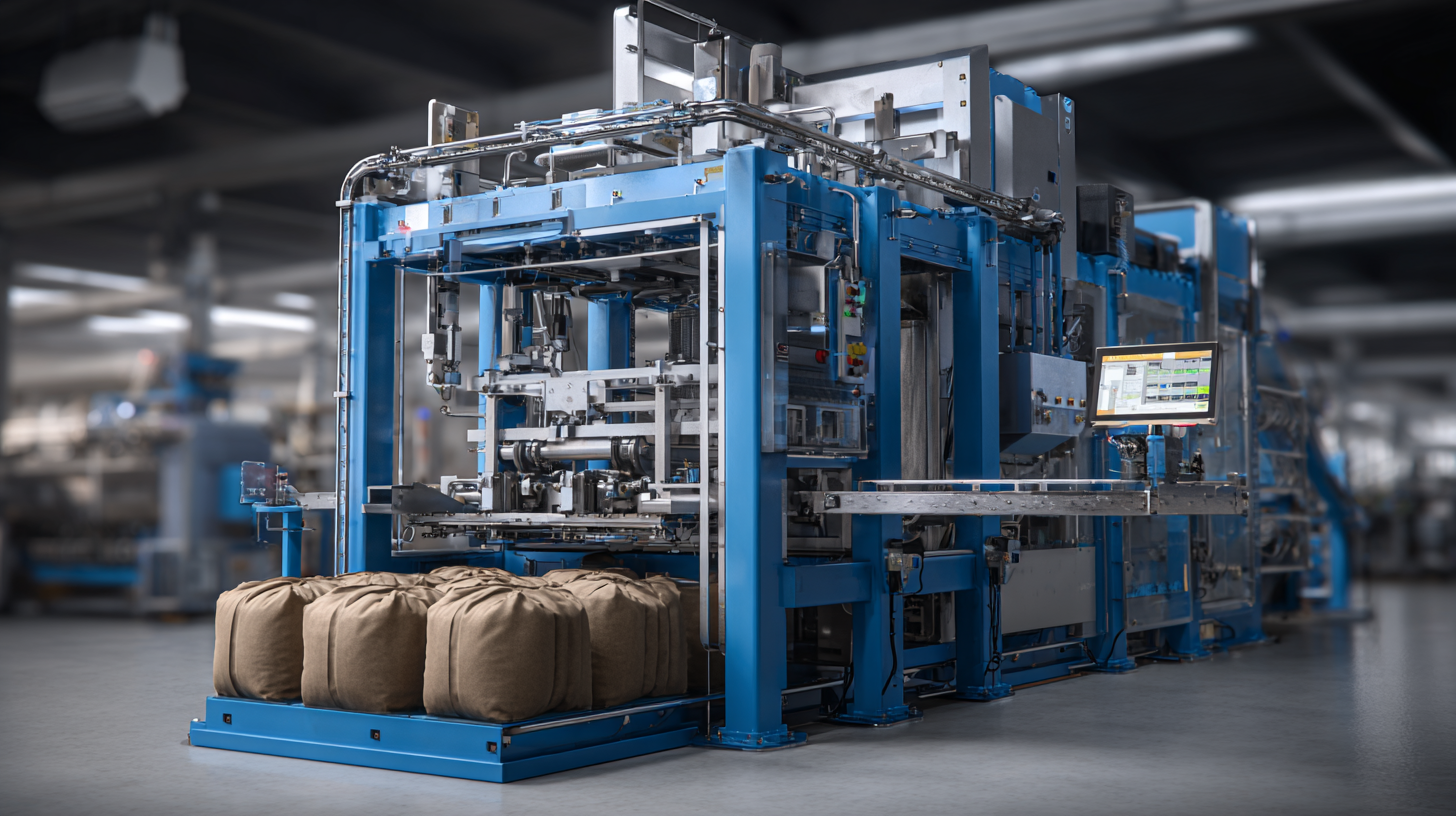

The Comprehensive Handbook for Selecting the Best Bag Filling Machine

In today's fast-paced manufacturing landscape, selecting the right bag filling machine is crucial for enhancing productivity and ensuring quality control in packaging processes. With the rise of "Made in China" goods that are exported worldwide, businesses must navigate the diverse options available in the market. This comprehensive handbook serves as a vital resource for manufacturers seeking to optimize their operations with the best bag filling machine tailored to their specific needs.

From understanding the various types of bag filling technology to evaluating key features and performance metrics, this guide will equip you with the knowledge necessary to make informed decisions. Whether you are involved in food production, pharmaceuticals, or any other industry requiring efficient packaging solutions, our insights will help you select a bag filling machine that not only meets your operational requirements but also supports your growth in a competitive global marketplace.

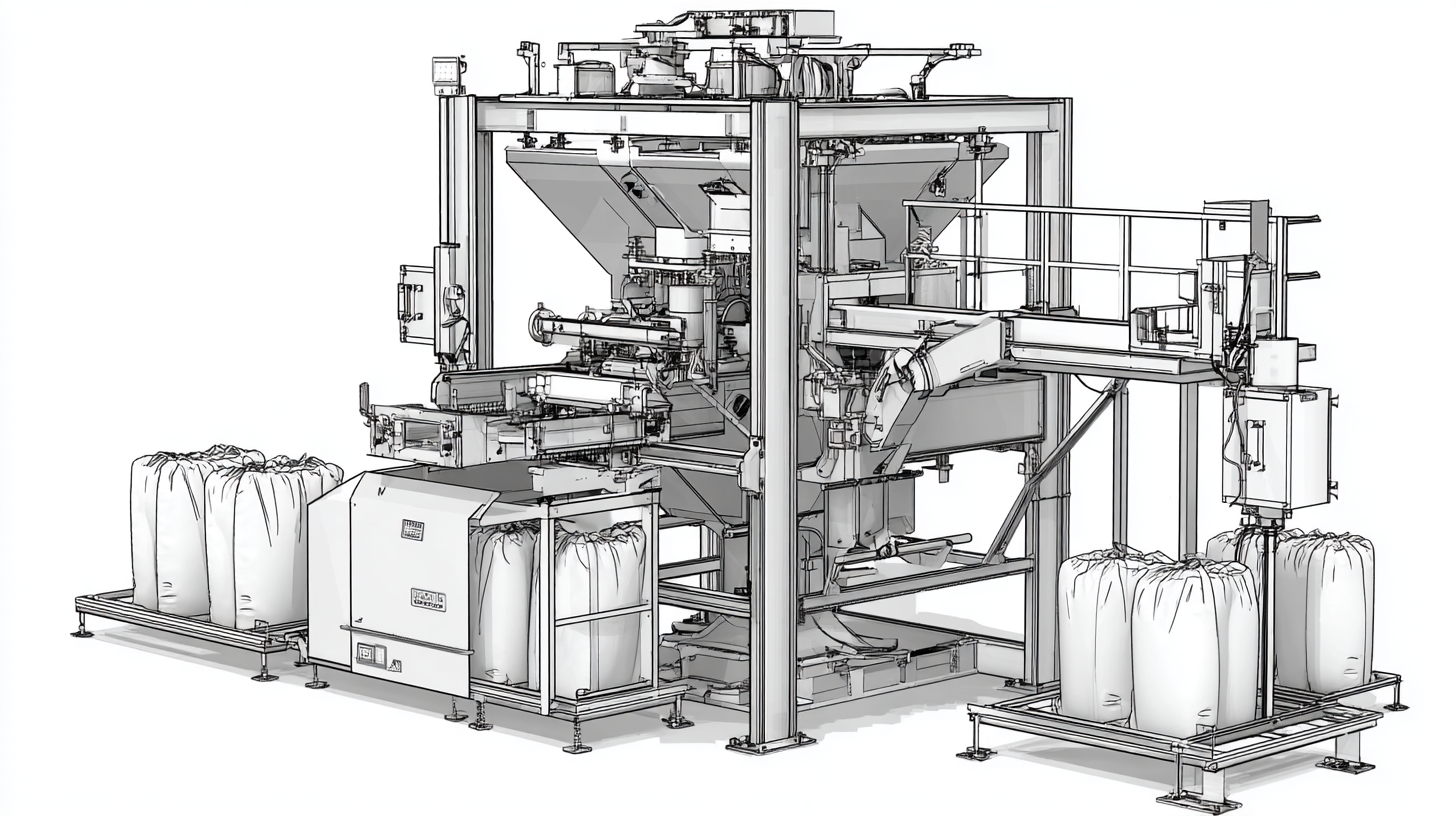

Understanding the Different Types of Bag Filling Machines and Their Applications

When choosing the right bag filling machine, it's essential to understand the various types and their specific applications. Each machine serves distinct purposes, depending on the materials being packed and the required throughput. For instance, the vertical form-fill-seal machines are gaining traction in the market due to their efficiency and versatility. A recent study comparing the heat sealability of thermoplastic films versus paper-based materials in these machines highlighted the different sealing geometries' effects on overall performance. The increasing demand for such machines is reflected in the projected growth of the form-fill-seal machines market, expected to reach USD 13.86 billion by 2034, up from USD 7.30 billion in 2024.

Moreover, environmental considerations are increasingly influencing the types of bag filling machines being adopted. The shift toward reusable packaging systems shows a growing consumer preference for sustainable alternatives to single-use options. This trend not only reduces waste but also encourages the packaging machinery market to innovate, with projections estimating over 4.5% CAGR from 2025 to 2032, potentially surpassing USD 69.58 billion by 2032. Understanding these trends helps industry players select machines that enhance efficiency while aligning with consumer values.

Key Factors to Consider When Choosing a Bag Filling Machine: Capacity and Speed

When selecting the ideal bag filling machine, capacity and speed are paramount factors that can significantly affect your production efficiency. Understanding the specific requirements of your operation can help you make a more informed decision. For instance, if your business anticipates high demand, opting for a machine with a greater capacity can ensure that you keep up with production needs without delays. Recent market trends suggest that the global liquid filling machines sector is witnessing substantial growth, indicating that investing in more advanced technology can contribute to long-term benefits.

**Tips:** When assessing capacity, consider not only the maximum output per hour but also the size and type of bags you will be using. Additionally, efficiency can often be enhanced by investing in high-speed machines that offer faster filling rates without compromising the quality of the fill. A notable example is a newly launched filling machine designed to achieve an impressive throughput of 360,000 capsules per hour, showcasing the technological advancements available in the market today.

Furthermore, it's essential to evaluate the machine's adaptability. A versatile bag filling machine can accommodate various products and packaging types, allowing for seamless integration into your existing production line. This flexibility can save costs and time as your business evolves. Always weigh the initial investment against potential productivity gains to ensure you select a machine that best fits your operational goals.

Industry Standards and Regulations Affecting Bag Filling Machine Selection

When selecting a bag filling machine, understanding the industry standards and regulations is crucial. The International Organization for Standardization (ISO) has established various standards that govern the performance and safety of packaging machinery. According to a recent report by Smithers Pira, adhering to these standards can enhance machine reliability and reduce the risk of equipment failure.

For instance, ISO 9001, which focuses on quality management systems, can significantly improve product consistency and operational efficiency, which are essential for businesses aiming to scale their operations.

Additionally, regulations from the Food and Drug Administration (FDA) and other relevant bodies dictate specific requirements for bag filling machines, especially in the food and pharmaceutical industries. Compliance with these regulations ensures that the machinery maintains hygiene and safety standards, thus protecting consumer health. A study by Freedonia Group indicates that manufacturing firms that prioritize regulatory adherence often see a 15% improvement in their compliance-related costs, emphasizing the financial benefits of investing in compliant machinery.

Therefore, when choosing a bag filling machine, it's imperative to consider not only performance specifications but also the extent to which the machinery meets established industry standards and legal requirements.

Cost Analysis: Budgeting for Your Bag Filling Machine Investment

When investing in a bag filling machine, a comprehensive cost analysis is crucial for ensuring your budgeting aligns with your operational goals. According to a report by MarketsandMarkets, the global bag filling machines market is projected to reach $5.2 billion by 2025, with a compound annual growth rate (CAGR) of 6.3%. This growth is largely driven by increasing automation in the packaging industry and the rising demand for efficient packaging solutions across various sectors. Understanding these trends can help you justify the investment in high-quality machines that enhance productivity.

The initial purchase price of bag filling machines varies significantly based on features, capacities, and automation levels. For instance, semi-automatic machines can range from $10,000 to $30,000, while fully automatic models may cost upwards of $100,000. A study from Grand View Research indicates that investing in more advanced machinery can yield a return on investment through reduced labor costs and increased throughput. Moreover, when calculating the total cost of ownership, it’s essential to consider maintenance, operational expenses, and potential downtime. By conducting a thorough cost analysis, businesses can make informed decisions that provide long-term value and profitability.

Latest Innovations in Bag Filling Technology and Their Impact on Efficiency

The landscape of bag filling technology is evolving rapidly, driven by innovations that enhance operational efficiency. With over 750,000 robots deployed in logistics, companies are witnessing significant transformations in inventory management and packaging automation. For instance, highly efficient robotics not only manage sorting and lifting but also automate the creation of customer-specific paper bags, leading to more streamlined operations and reduced turnaround times. Reports suggest that integrating robotic arms into packaging lines can increase productivity by up to 50%, underscoring the importance of technological advancement in bag filling machinery.

Additionally, the launch of new multi-lane stick packing machines is set to revolutionize the sector, optimizing output and reducing waste. Industry insights reveal that automated systems—such as those in advanced baggage handling—enhance process efficiency and customer satisfaction by minimizing delays. Innovations across the board are not just about speed; they also contribute to sustainability, with many new technologies designed to lower environmental impact while improving operational performance. These developments reflect a growing trend towards intelligent automation in packaging, positioning businesses to meet the evolving demands of the market efficiently.